DIY Vacuum Casting Table – Investment Casting

In the world of jewelry making, the process of casting intricate designs in precious metals requires precision and specialized equipment. Determined to embark on this artistic journey without breaking the bank, I took on the challenge of building my own vacuum casting table. By repurposing an old table acquired from Facebook Marketplace, along with aluminum tubing and a sheet of 1/8″ steel, I constructed a cost-effective solution to aid in the creation of exquisite sterling silver jewelry.

Inspiration struck when I stumbled upon an inexpensive table listed for $20 on Facebook Marketplace. Seeing its potential, I immediately envisioned it as the foundation for my future vacuum casting table. With a sturdy frame and a workable surface, it provided an ideal starting point. Excitedly, I began gathering the additional materials required for the project, including aluminum tubing to form the structure and a sheet of 1/8″ steel to serve as the table surface. These components would come together to create a workspace that would bring my jewelry-making aspirations to life.

After carefully measuring and cutting the aluminum tubing to form my vacuum chamber, I bonded the pieces together with steel epoxy putty, ensuring stability and durability. I then affixed the sheet of 1/8″ steel to the tabletop, resulting in a smooth and robust work surface.

One of the main challenges I faced during the construction was acquiring the necessary equipment to connect the vacuum pump to the table. However, with some resourcefulness and diligent research, I was able to source the required fittings and hoses, enabling me to establish a proper vacuum system. This system would create the necessary negative pressure to aid in the casting process, ensuring the removal of any air bubbles or imperfections in the molten sterling silver.

After overcoming the construction challenges, I connected the vacuum pump to the table, eagerly anticipating the first test run. With bated breath, I activated the pump and observed as the vacuum pulled air through the chamber, creating a seal and removing any unwanted air pockets. It was a moment of triumph as I witnessed the table’s functionality come to life, bringing me one step closer to realizing my jewelry-making dreams.

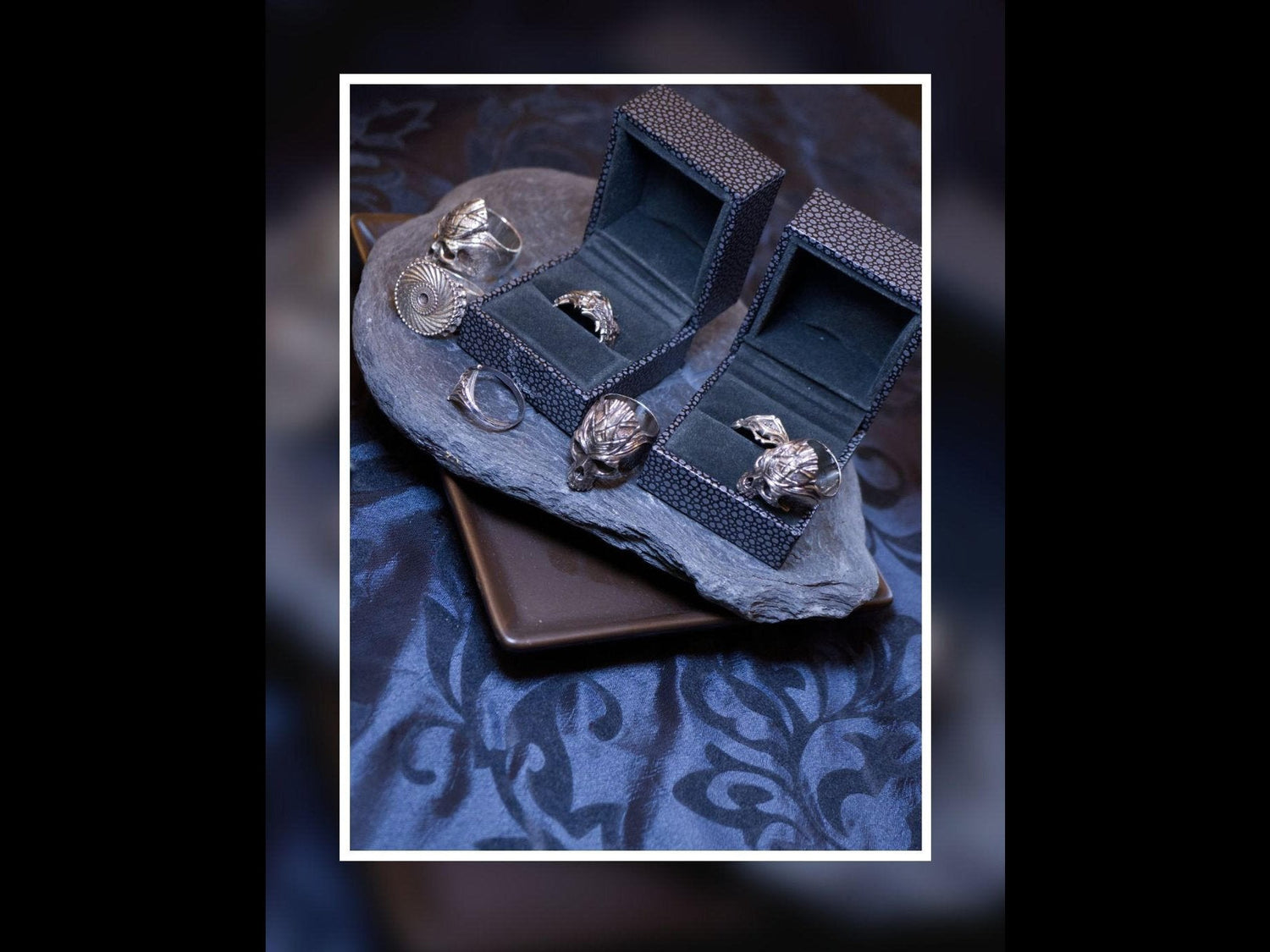

With a functional vacuum casting table at my disposal, I could now embark on the creation of beautiful sterling silver jewelry pieces. The vacuum system, coupled with the precise control it offered, allows for the casting of intricate designs with remarkable accuracy and detail. The removal of air bubbles ensures the resulting jewelry possesses a flawless finish, captivating the eyes of those who beheld it.

Through resourcefulness and a passion for craftsmanship, I transformed an old table and a few additional materials into a functional vacuum casting table. By connecting it to a vacuum pump, I created a tool that enabled me to cast exquisite sterling silver jewelry with precision and finesse. This DIY project not only saved me a significant amount of money but also provided me with a sense of accomplishment and pride. With my newly built vacuum casting table, I look forward to crafting unique and beautiful jewelry pieces that will captivate the hearts of everyone who wears them.